Does Needlepoint Bipolar Ionization Improve Air Quality?

By Karpinski Engineering | May 26, 2021

Key Takeaways

- After installing the needlepoint bipolar ionization system, the amount of positive and negative ions in the building substantially increased.

- Post-installation, the level of total volatile organic compounds –a proxy for the level of viruses and bacteria in a space – dramatically decreased.

- The needlepoint bipolar ionization system Karpinski installed has been UL listed for no ozone and no byproducts.

- The system requires very little power and maintenance.

As part of our COVID-19 mitigation strategy, we installed a needlepoint bipolar ionization (NBPI) system at our Cleveland headquarters. The system is designed to reduce the amount of contaminants such as viruses and bacteria in the air. There haven’t been a lot of third-party studies of the technology. Because of the lack of data, ASHRAE, a leading authority on all things HVAC, has taken a “wait and see” stance. We wanted to add to the body of data.

Based on the results we’re seeing, NBPI substantially reduces the amount of volatile organic compounds in a space – a key indicator of the presence of viruses and bacteria.

In this article, we’ll look at how the technology works and how we know it’s effective, using Karpinski’s installation as a case example.

How It Works

Needlepoint bipolar ionization (NBPI) is designed to clean the air through the process of ionization. The NBPI system distributes positive and negative ions through the air, where they attack and kill pathogens such as viruses, mold, and bacteria. NBPI also causes particles to clump together (particle agglomeration), which improves filtration effectiveness. Finally, it oxidizes odorous gases, breaking them down into basic compounds free of any smell.

It’s worth noting that ions are naturally present in the air. What a NBPI system does is increase the amount of ions in the air to a level where they can inactivate pathogens.

A NBPI unit is typically installed on the upstream side of the coil in the air handling unit. The Karpinski installation took about a day, plus additional time for linking it with the building automation system (BAS) so we could get system performance data.

The NBPI unit we selected can be retrofitted into just about any building. One advantage of this system is that it requires very little power – any voltage from 24-240V. That power is almost assuredly available at the air handling unit. Long-term, the unit requires very little maintenance.

How Do You Know It’s Effective?

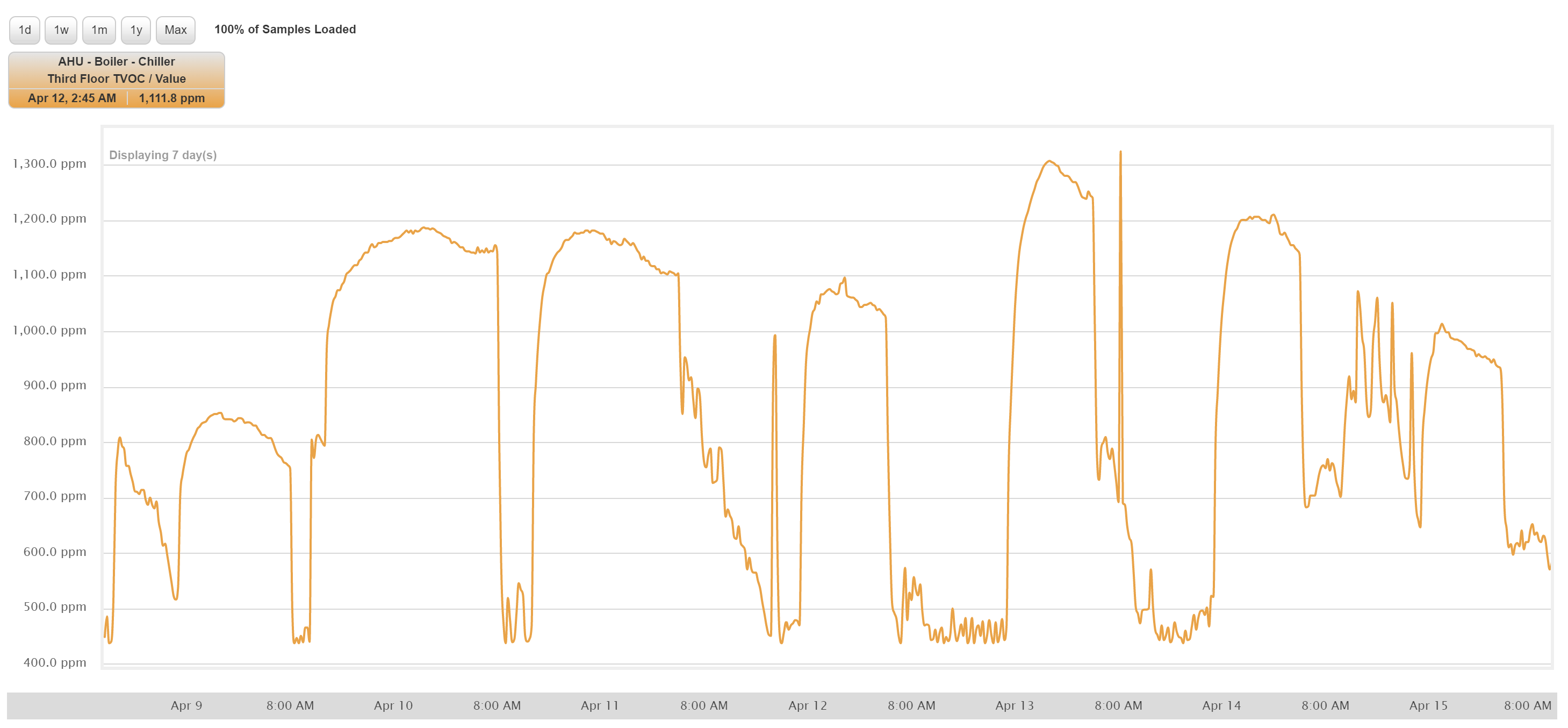

To evaluate the effectiveness of NBPI, we measure the total volatile organic compounds (TVOCs) in a space. There tends to be a direct relationship between the level of TVOCs and the level of bacteria and viruses in a space. The lower the level of TVOCs, the lower the level of bacteria and viruses, and vice versa. It’s similar to the way we use CO2 levels to determine whether people are occupying a space. For TVOCs, under 500 ppm is a good target.

Karpinski’s NBPI system is linked to our BAS so we can gather and view the data. When our NBPI system is running, the TVOC level drops dramatically – which suggests that the amount of bacteria and viruses decline too.

A couple interesting notes about the dashboard: Our HVAC and our NBPI system runs during standard office hours, and the dashboard shows that TVOC levels are generally below the 500 ppm target. At night, when the system is not distributing ions through the office, the VOC level rises. Additionally, once the system was running, we noticed random spikes in TVOC levels. We ultimately attributed the spikes to the TVOC sensor’s location near the office coffee bar. People give off VOCs, so their presence near the sensor impacts the TVOC readings.

Another indicator of the NBPI system’s effectiveness is the comparative absence of mold and/or fungus in the air handler post-installation. It’s typical to find some mold or fungus in buildings, and it can be harmful or benign. There was growth in our air handler (see photos below) which was cleaned prior to the NBPI system installation. Even though the mold/fungus was cleaned out, we would generally expect it to grow back – similar to how mildew in your shower always comes back. We didn’t change anything about the air handler environment that would cause it to go away. However, more than six months after installation, we aren’t seeing any growth in the unit.

The product Karpinski installed has been UL listed for no ozone and no byproducts. (Older bipolar ionization technology had high levels of ozone byproduct.) This is important for two reasons. One, we obviously don’t want to use products that release ozone or other harmful byproducts. Two, it frees designers and clients to use the technology. ASHRAE requires all air cleaning technologies meet UL 2998 (See ASHRAE Standard 62.1-2016 Ventilation for Acceptable Indoor Air Quality, Addendum AJ [opens as a PDF]).

Thank you to Ben Arnett of Critical Aire for providing NBPI data for the article.