Charting the Course to Achieve Campus Carbon Emissions Goals

By Joe Hofstetter | Jul 24, 2023

Over the past decade, there has been a significant and remarkable increase in the number of campuses establishing carbon emission reduction goals. This trend highlights our progress toward meeting important deadlines and advancing sustainability initiatives. These targets are driving strategic operational changes and the adoption of measurable metrics to track our progress. However, the question arises: how can we effectively translate these goals into actionable items that align with cost-effective long-term planning for campuses?

The motivation to achieve a carbon-neutral society is being driven both from the top-down and the bottom-up. Both leadership and constituents of educational organizations are seeking guidance from campus facilities leaders and experts to lead the way. The convergence of these motivations often occurs within facilities, planning, and operational leadership, where stakeholders are looking for answers and decisive action.

Consequently, numerous discussions have been sparked, focusing on the development of effective strategies to meet energy and carbon emission reduction targets. Many of these discussions revolve around addressing building operational emissions, the role of electrification in this process, and the necessary steps to align our infrastructure with these goals.

Defining Carbon Emissions for Today’s College Campus

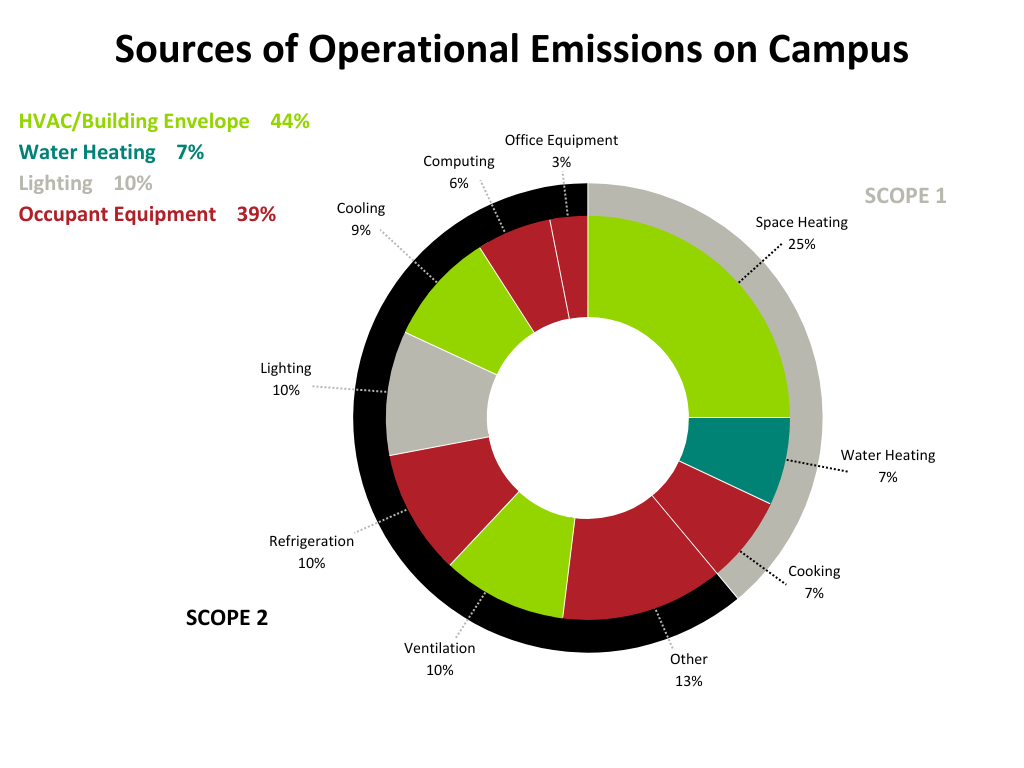

Operational emissions, distinct from embodied carbon related to materials and construction, are typically associated with the utility energy consumption within a campus and the resulting emissions it generates. These emissions are commonly categorized into three “scopes.”

Scope 1 encompasses an organization’s direct greenhouse gas (GHG) emissions, such as those from burning fuel in boilers, furnaces, and fleet vehicles. Scope 2 refers to indirect emissions resulting from the organization’s purchase of energy, such as electricity. The emissions occurring at the power plant are attributed to the energy user. And scope 3 covers indirect emissions caused by the organization, including business travel and employee commuting.

It’s important to note that campuses leading in emissions tracking consistently account for scope 1 and 2 emissions, but their inclusion of scope 3 emissions may vary.

Solutions for Reducing Campus Emissions

The argument in favor of electrification is based on the fact that no matter how efficient something is, if it relies on fossil fuels in scope 1, complete elimination of those emissions becomes impossible. Electrification offers the opportunity to eliminate carbon emissions entirely while still providing power to our buildings.

However, this then shifts the carbon emissions issue to our electrical production. The current average grid electricity must be addressed through onsite renewable generation, power purchase agreements for clean energy, or a significant improvement in overall grid cleanliness compared to the present state. This solution requires giving time for technology and the grid to resolve the challenge of clean power generation.

How Thermal Electrification Can Lower Building Emissions

For universities, electrification is a broad topic encompassing various aspects, including electric vehicle charging, kitchen operations, and building thermal electrification. Each of these areas presents its own challenges, but thermal electrification particularly relates to the existing infrastructure and long-term planning of our campuses.

Thermal electrification involves converting fossil fuel systems, such as gas-fired boilers and domestic hot water heaters in buildings, to electric alternatives. However, it’s crucial to recognize that this transition is not as simple as replacing them with electric resistance heat sources. Karpinski Engineering recently encountered this question when tasked with replacing a campus central plant steam boiler. University leadership questioned why the existing natural gas boiler couldn’t be replaced with an electric system.

The answer was clear after careful consideration: we’re not ready yet.

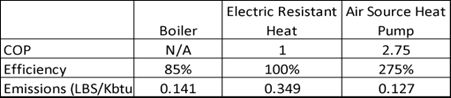

Ideally, when implementing a thermal electric solution, the goal is to utilize heat pump technology that draws energy from the outdoor ambient environment or the earth using a geothermal heat pump system. These systems are effective in producing low-temperature hot water (ranging from 120-140°F).

However, many university campuses face the issue that their buildings were designed to rely on steam or high-temperature hot water, and their heating distribution systems are not equipped to transport energy at lower temperatures. Legacy buildings cannot effectively operate at these lower temperatures, and the campus lacks the necessary low-temperature hot water distribution to implement central plant heat pump system.

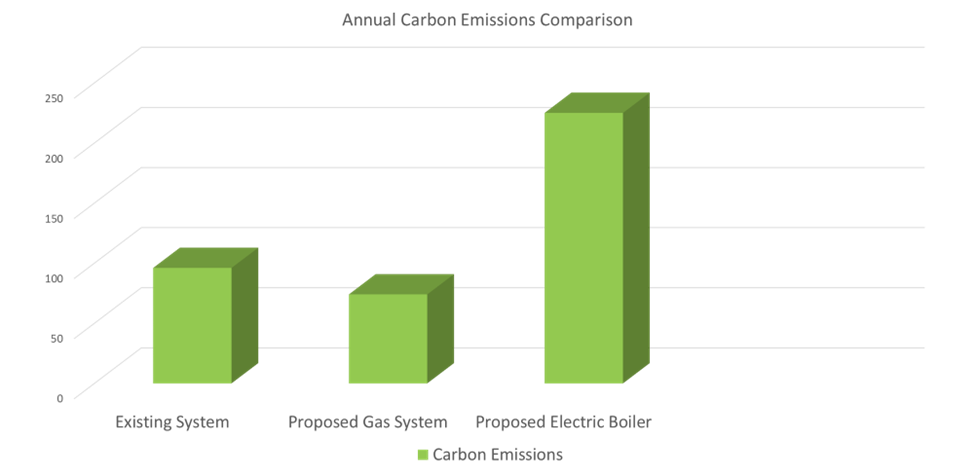

Consequently, to generate steam for the existing distribution, the replacement boiler would need to be an all-electric resistance boiler. However, an electric resistance boiler served by the Midwest electric grid would result in carbon emissions 2.5+ times higher than that of natural gas. Therefore, the decision was made to replace the steam boiler with another gas-fired boiler, with the potential plan to make it the last replacement.

The question then arises: “Where do we go from here?”

A Master Plan to Reduce Campus Building Emissions

The simple answer is that a plan needs to be established. When reviewing options for the boiler replacement, emissions related to different sources were considered. In most of the Midwest (and thus the overall U.S. average), electrification, even in its best design, only slightly improves carbon reduction today. However, for universities located in other regions of the U.S., like western New York or the Northeast, could benefit greatly and sooner from an early all-electric plan because these areas have a different utility emissions profile.

This highlights the importance of region-specific energy master plans that address the unique challenges faced by organizations. An energy and infrastructure master plan can account for long-term goals, energy and carbon emission future assumptions, and generate metric-based results at specific project intervals. By creating such a plan, it becomes possible to generate buy-in and establish phases based on measurable metrics.

To effectively achieve thermal electrification as a long-term decarbonization goal, the university must address or continue addressing the following:

- Invest in infrastructure for low-temperature hot water distribution, including circulation pumps and piping, utility tunnels, etc.

- Incorporate low-temperature heating hot water design into replacement HVAC equipment for each building and end devices.

- Develop a multi-phased approach to convert central plant equipment from natural gas to electric heat pump technology. In some cases, this may be a multi-phase approach that includes converting to high-efficient condensing boilers, incorporating heat recovery chillers, and finally expanding to a more comprehensive heat pump plant.

However, it’s important to note that the overall decarbonization plan should encompass more than just thermal electrification of the plant. Energy efficiency and reduction of energy use remain the most cost-effective and immediate measures that campuses can invest in to immediately reduce carbon emissions. The energy cost savings resulting from these improvements can also contribute to the conversion of existing systems and reduce the plants’ peak capacity needs.

Lower Energy Costs with Energy Audit Assessment

Typically, an energy audit or assessment is used to identify the most effective improvements for reducing energy costs. With minor adjustments to the process and consideration of the organization’s sustainability plans, these studies can be adapted into decarbonization audits or studies that address both short-term reduction opportunities and the energy master planning required for complex systems and infrastructure needed for thermal electrification.

With over 20 years of experience in sustainability engineering consulting, Karpinski Engineering has been actively supporting building sustainability through various means such as design, predictive energy modeling, large-scale geothermal systems, building energy retrofits, and carbon reduction infrastructure projects. We have found that our expertise and tools effectively assist clients in developing energy and decarbonization master plans that support the long-term implementation of necessary improvements to successfully meet the targets set by many higher education organizations.