Modernizing the Heart of Surgical Operations: Rethinking Sterile Processing Departments

By Dave Curfman and Katie Lee | Oct 23, 2025

In healthcare facilities, few departments are as vital and complex as the Sterile Processing Department (SPD). These behind-the-scenes spaces are responsible for cleaning, sterilizing, and preparing surgical instruments, making them essential to patient safety and surgical efficiency. Yet, many SPDs are operating with infrastructure and workflows that haven’t kept pace with modern demands.

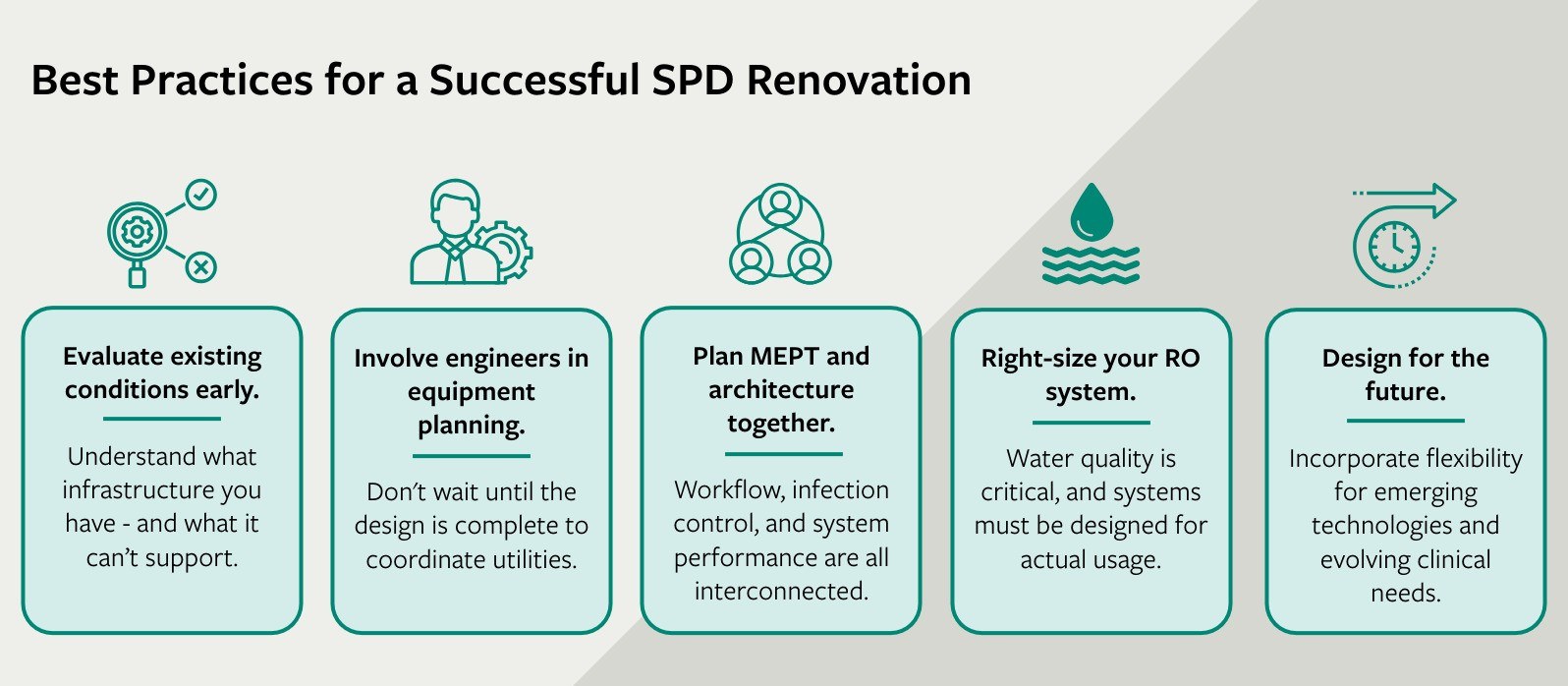

This article explores the essential elements of a successful Sterile Processing Department renovation or modernization. It highlights the importance of regulatory compliance, effective equipment coordination, and utility planning while also addressing common challenges and offering practical strategies to help healthcare organizations create high-performing, future-ready SPDs.

Sterile Processing Departments play a vital role in infection prevention, surgical efficiency, and overall patient safety. However, many facilities continue to rely on aging infrastructure, outdated workflows, and equipment that’s past its prime. Renovating an SPD involves more than upgrading sterilizers; it requires a thoughtful redesign of how space, systems, and staff work together to enable safe and streamlined care.

Codes Set the Floor, Not the Ceiling

Regulatory standards like FGI 2022, ASHRAE 170, and ANSI/AAMI ST79 & ST108 provide the foundation for SPD design. They define requirements for airflow, pressure relationships, room separation, and equipment layout. But compliance alone doesn’t guarantee performance.

High-performing SPDs go beyond code. They align design with clinical workflows, anticipate future needs, and create environments that enable the well-being of patients and staff. All the supporting systems must work together to achieve results that mitigate cross-contamination and support infection prevention objectives. For example, spaces with pressure requirements can’t just rely on the HVAC system. They need to be separated by properly sealed full-height walls or maintaining that pressurization isn’t realistic.

Equipment Planning: The Hidden Complexity

One of the most underestimated aspects of SPD renovation is equipment planning. Replacing a sterilizer or cart washer isn’t always a simple swap. Newer models often have tighter tolerances, higher or new utility demands, and different maintenance requirements. A “one-for-one” replacement can trigger unexpected infrastructure upgrades, especially in older facilities.

We’ve seen projects where new sterilizers had difficulty meeting water pressure testing requirements during verification, even though the specs matched the old units. The culprit? Pressure drops caused by flexible hoses and unmetered flow. These kinds of issues underscore the need for early coordination between engineers, equipment vendors, and facility staff.

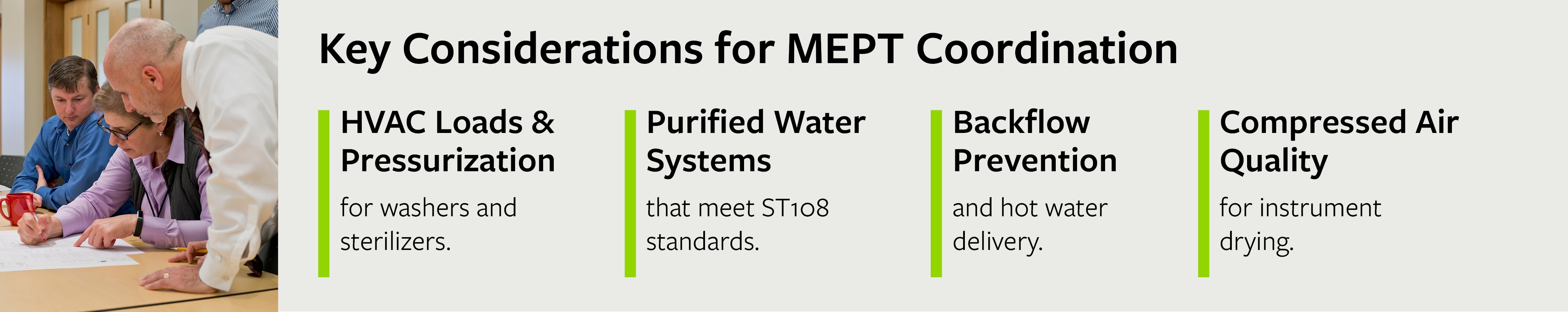

MEPT Coordination: Where Design Meets Reality

Mechanical, electrical, plumbing, and technology (MEPT) systems must be designed in parallel with architectural planning. This is especially true in renovations, where ceiling space is limited, and existing utilities may not align with new equipment. Ignoring these details can lead to costly rework, downtime, and performance issues post-installation.

Phasing and Temporary Solutions

Renovating an SPD while maintaining operations is a logistical puzzle. Phased construction is often necessary, but it comes with risks - especially when piping mains (sanitary, water, steam, compressed air, etc) or air handling systems are shared across departments.

Some facilities consider mobile SPD trailers or off-site processing, but these options can be cost-prohibitive. For example, mobile SPD trailers also require the engineering design of the utilities to support the trailer, such as electrical services, water & sanitary lines, IT fiber for network connections, and sprinkler system tie-ins. When phasing is the only viable path, early planning and clear communication are essential. Temporary setups must be carefully designed to maintain compliance, minimize disruption, and allow physical space for both ongoing sterilization and the construction team’s work.

Looking Ahead

As surgical services expand and technology advances, the demands on SPDs will only grow. Renovating these spaces is a chance to not just meet today’s standards, but to prepare for tomorrow. With the right team, thoughtful planning, and a commitment to performance, SPDs can become more than just support spaces - they can be strategic assets in delivering safe, efficient care.