Design Smarter, Build Better: Lean & IPD Strategies for Large Healthcare Projects

By Matthew Morgan | Jul 07, 2025

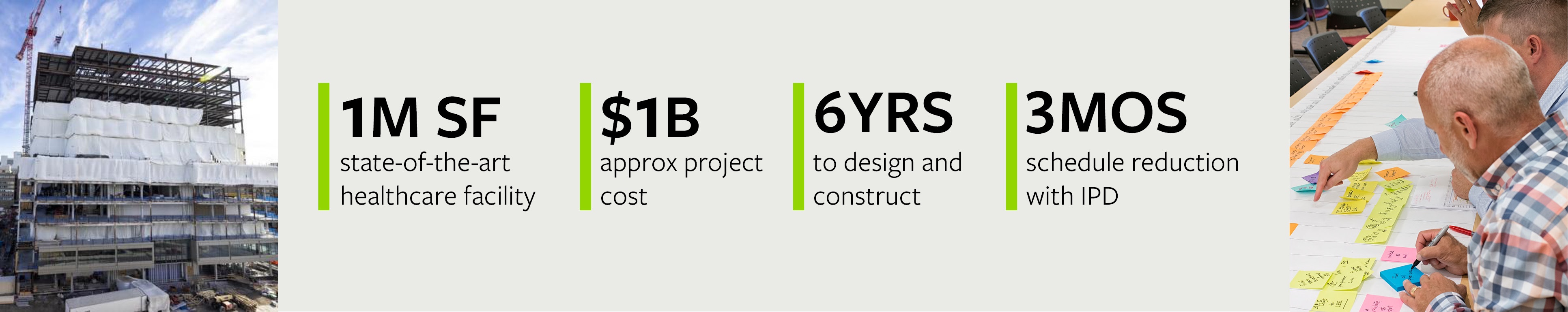

Large-scale healthcare construction projects require careful coordination, long-term planning, and the ability to adapt quickly. As project size increases, so do the risks, decisions, and moving parts. When Cleveland Clinic set out to build its new, 1 million square-foot Neurological Institute, it needed a strategy that could meet ambitious goals: deliver within six years and keep the cost under $1 billion. That meant rethinking traditional approaches.

By combining Lean principles and Integrated Project Delivery (IPD), the project team created a collaborative structure that reduced waste, prioritized value, and enabled the owner to make informed decisions quickly. For health systems planning significant capital investments, this approach offers a model worth studying.

Pull Planning: Building the Timeline Backward

From the outset, the team used pull planning to define the project’s critical path. Working backward from major milestones, stakeholders across disciplines mapped out the tasks needed to meet each deadline, along with their sequencing and durations. This provided the entire team with a clear view of interdependencies and helped identify schedule risks early on.

For a project of this scale, one of the most important insights was just how much needed to happen at the same time. Pull planning made it clear that construction couldn’t wait for design to be fully complete. The team identified early packages for foundations, structure, and major MEP systems, allowing site work and procurement to begin while design continued.

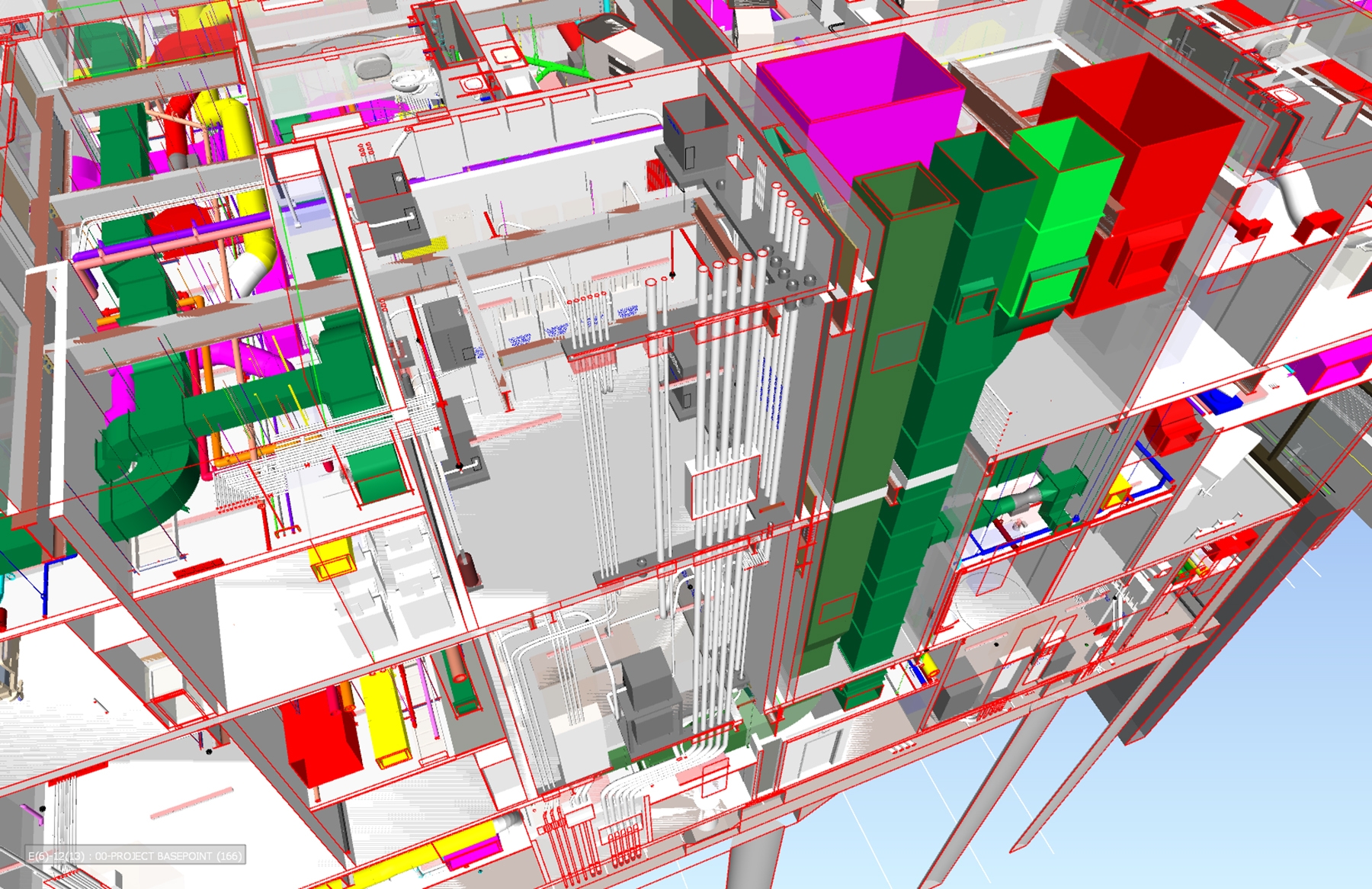

While early packages are relatively common on large projects, this team took things a step further. Trade partners were asked to begin drawing the MEP coordination model early in the design process, using engineering diagrams and design guidance rather than fully detailed construction documents. This strategy enabled the coordination model and critical items, such as MEP hanger locations, to stay ahead of the concrete pour schedule, keeping field work moving without delays.

Virtual Design: Coordination at Full Scale

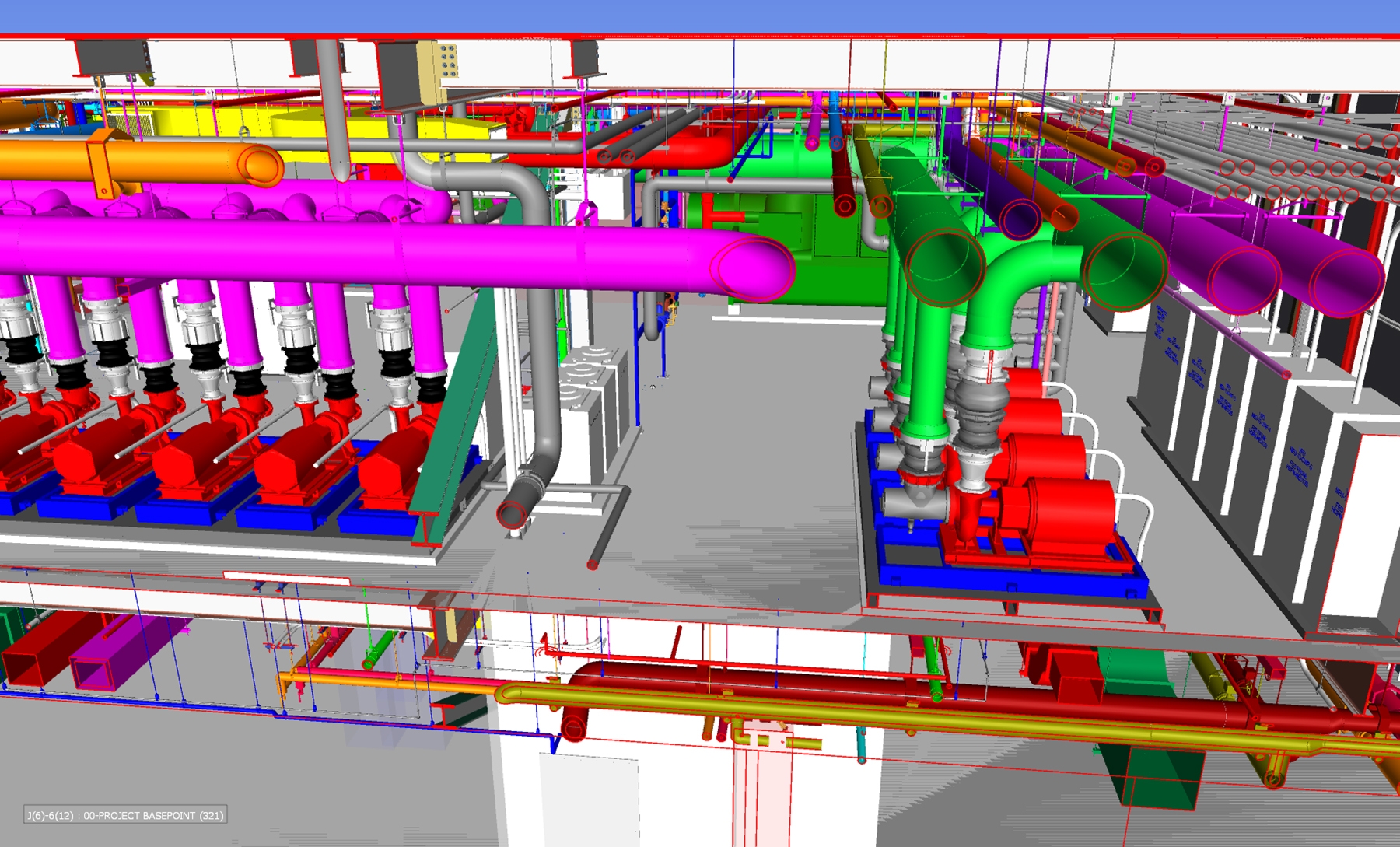

With over one million square feet and dozens of intersecting systems, coordination wasn’t optional, it was essential. As revealed during pull planning, the team recognized the need to align design and construction efforts early. Using shared Revit models, trade partners and the engineering team collaborated in real time throughout the design and coordination process.

Model sharing and early clash detection helped eliminate issues before they ever reached the job site. Teams used these models to validate constructability, resolve layout challenges in tight spaces, and reduce field rework.

One of the most significant outcomes was the ability to avoid duplicative work. Instead of having the design team model systems once, followed later by the construction team, both groups worked in a single shared model. This eliminated redundant effort and accelerated decision-making.

Shop Drawings for Permit: A Different Way to Work

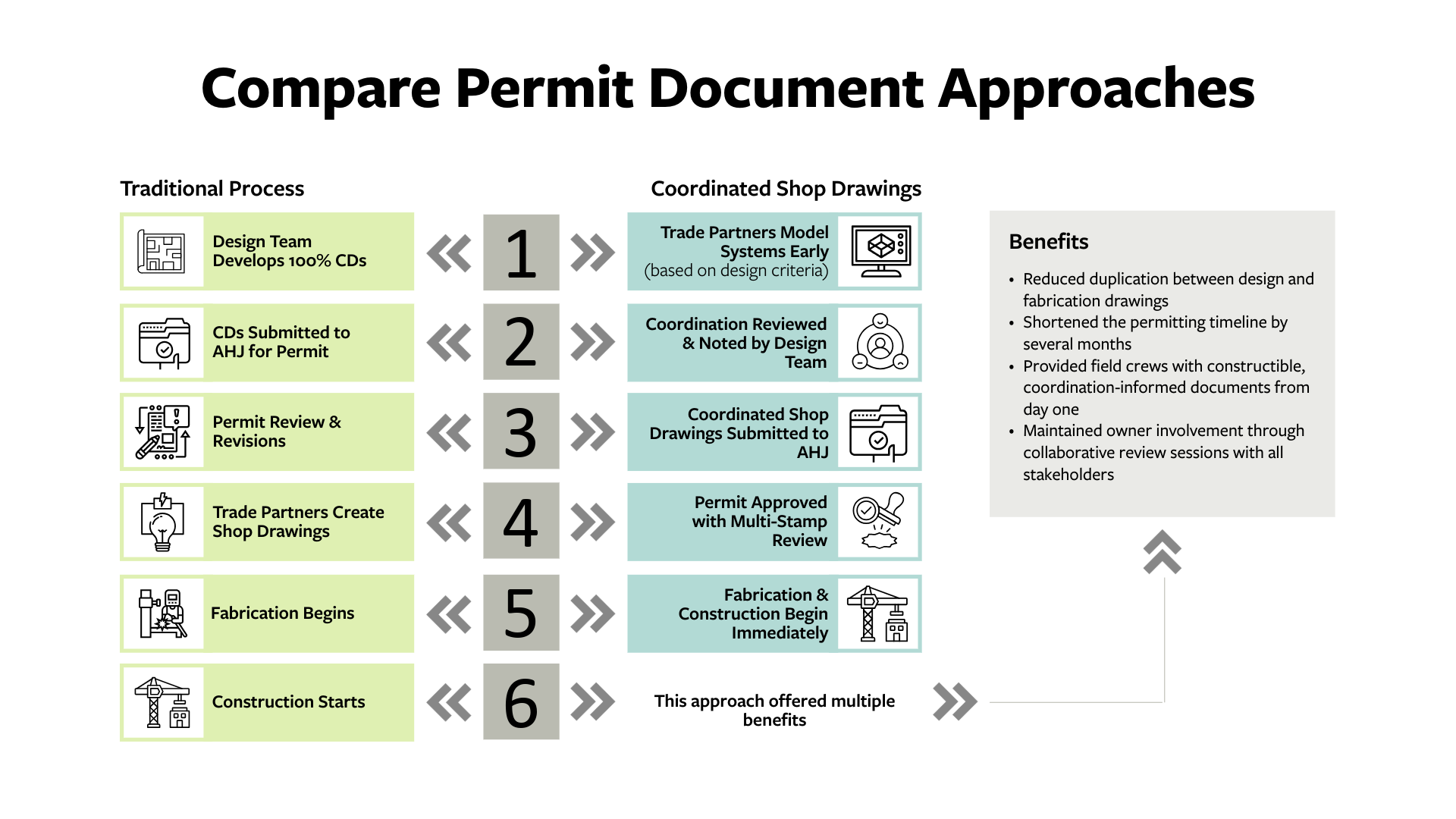

To keep the schedule on track, the team used coordinated shop drawings in place of traditional construction documents for permitting - a significant shift, especially for a project of this scale.

The design drawings included coordinated ductwork and piping layouts that were directly input by the trade partners, with review and markup by the design team. These drawings had a different appearance from standard permit sets, but they met the necessary code requirements and greatly improved process efficiency.

Shop drawings were developed in parallel with the design phase and finalized quickly once permits were approved, allowing fabrication and installation to move forward without delay.

For Owners Planning Their Next Big Project

The Cleveland Clinic Neurological Institute project demonstrates what’s possible when Lean and IPD are applied at scale. For other health systems facing high-stakes capital programs, this approach can help reduce risk, control costs, and maintain flexibility in uncertain environments.

However, it requires commitment from leadership, partners, and every team member involved. With the proper structure and shared accountability, Lean and IPD don’t just deliver projects - they build stronger teams and better buildings.

Top 5 Lessons from This Project

- Plan for early decisions and design to support them

- Let procurement strategy shape the design timeline

- Use virtual coordination to eliminate field issues

- Involve trades early through design-assist or IPD

- Treat permitting as a collaborative process, not a final hurdle

Project Team

Cleveland Clinic | Owner

Stantec | Architect & MEPT Engineering

Turner | Construction Manager

Hopkins Architects | Executive Architect

Karpinski Engineering | MEPT Engineering

LeMessurier | Structural Engineer

Moody Engineering | Civil Engineer

Knight & Stolar | Landscape Architect

R Engineering Team | MEP 4th Floor

Robert P. Madison International | Architectural Support

Advanced Engineering Consultants | MEP 10th Floor

For more details on the Cleveland Clinic Neurological Institute, follow the link: https://my.clevelandclinic.org/departments/neurological/about/neurological-institute-building

*NOTE: Cleveland Clinic uses the OLED (Owner-Led) Project Delivery Model. This model is a proprietary version of the Integrated Project Delivery Model where, through Owner leadership, they create a project culture where people in different roles relate to each other so that they put the collective purpose of the construction project first. (Credit: Cleveland Clinic OLED Guide & Playbook Edition 2, October 2023).

Keep up-to-date and in-the-know.

Interested in receiving the latest news and insights from Karpinski? Sign up to receive our Going Beyond emails.