With Pennsylvania’s Building Code Update, 4 Big Changes to HVAC Projects

By Dan DiCriscio | Mar 21, 2019

Pennsylvania has adopted the 2015 IECC. Here’s what owners and facility managers can expect from new HVAC projects.

Updated with clarifications regarding the 2015 IECC’s compliance options.

Pennsylvania’s adoption of the 2015 IECC is changing how we design and operate buildings, from HVAC systems to lighting controls to building envelopes. In this article, we look at 4 of the biggest changes for HVAC systems, along with their impact on building operations. (In a separate article, we’ll cover some of the biggest changes to power and lighting requirements.)

First, some quick background.

The new code significantly decreases how much energy buildings can use (by limiting the energy consumption allowed). That’s largely because the 2015 IECC draws on ASHRAE 90.1-2013 (Energy Standard for Buildings Except Low-Rise Residential Buildings). (Side note: 90.1-2013 is one of the options for code compliance.) Previously, the Pennsylvania code referenced IECC 2009/ASHRAE 90.1-2007. Since then, ASHRAE has made some big changes in terms of system and energy requirements.

Under ASHRAE 90.1-2013, new commercial buildings will consume on average 19.9% less energy than if the same building was constructed in 2007 (based on information from the U.S. Department of Energy and Pacific Northwest National Laboratory). With both the ASHRAE 90.1-2013 and the 2015 IECC compliance options, system components that had been optional, or considered good practices, are now required.

The results are good for buildings owners and occupants: reduced energy consumption, better system controls, better thermal comfort, and a healthier building environment.

Here are the 4 big HVAC changes that owners and facilities staff can expect. For the purposes of this article, we’re comparing ASHRAE 90.1-2013 to 90.1-2007. However, these requirements are part of the 2015 IECC compliance options as well.

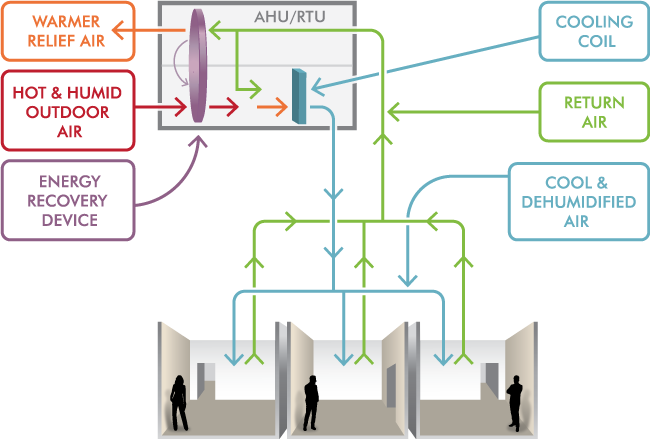

1. Energy Recovery Systems Are Required More Often

The purpose of an energy recovery system is to recover some of the energy used to condition outside air and use it to precondition the new outside air being brought in. As a result, the HVAC system expends less energy conditioning outside air.

Under ASHRAE 90.1-2007, HVAC systems needed energy recovery when they used 70% outside air and were greater than 5,000 CFM. With 90.1-2013, the thresholds for needing energy recovery systems have both lowered and broadened.

Today, hospitals, K-12 schools, higher education institutions, and larger office facilities can generally expect to see energy recovery on their projects. Building renovations may need energy recovery where they didn’t previously. For example:

- A hospital where the HVAC systems are operating more than 8,000 hours/year will need energy recovery.

- A school with a 40% outside air, 20,000 CFM air handler will need energy recovery. (Under ASHRAE 90.1-2007, it wouldn’t have.)

2. More Equipment Needs Variable Speed Motors

Most HVAC systems are running at part load for most of the year. Some days, the system doesn’t need to work as hard as others. Variable speed motors allow the HVAC system to react more accurately and efficiently to the building load (e.g., people, machines) and outdoor environment.

ASHRAE 90.1-2013 has broadened the requirements for using variable speed motors on fans and pumps. As with energy recovery systems, you’re now going to see variable frequency drives (VFDs) more often. Examples include:

- Packaged DX Rooftop Unit: Any fan motor associated with DX cooling requires a VFD

- Fan Motors Associated with Chilled Water or Evaporative Cooling: Require VFD when motor is greater than ¼ hp

- Chilled Water Pump: Requires a VFD if greater than 5 hp (90.1-2013 parallel path only)

3. New Minimum Requirements for HVAC Controls

The new HVAC controls requirements are designed to keep HVAC systems from doing more work than a building needs. They impact ventilation optimization, supply air temperature reheat limits, and supply air temperature reset. These items first appeared in 90.1-2010. For example, the supply air temperature reheat limit is now 20 degrees F above the occupied room temperature.

4. HVAC Systems Need Demand Control Ventilation More Frequently

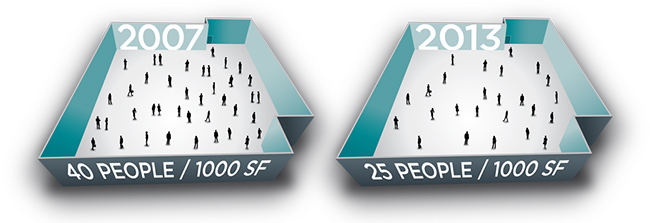

Demand control ventilation allows the HVAC system to respond more effectively to changing load requirements in different zones throughout the building. As occupancy changes, the system can reduce or increase the amount of outside air brought in.

With ASHRAE 90.1-2013, demand control ventilation is required in more spaces because the occupancy density threshold has lowered. In decent-sized spaces with varied occupant diversity (such as conference rooms and classrooms), you’re now much more likely to need demand control ventilation.

For example, under 90.1-2007, a space greater than 500 SF with a people density greater than 40 people/1,000 SF needed demand control ventilation. Now, in the same size space, a people density of 25 people/1,000 SF requires demand control ventilation (see illustration below).

Education Is Key

Some of these requirements will change how facilities staff and occupants interact with their building.

Facilities teams will need training so they know how the new systems operate and what options they have. For example, with HVAC systems that are designed to adapt to the environment automatically, manual overrides can actually work against energy efficiency and occupant comfort.

Occupants may find some of the new functions limiting. For example, the new HVAC control requirements mean they won’t be able to crank the thermostat to 80 degrees. Letting occupants know what to expect can help with the transition and limit service calls.

The updated code is demanding more in terms of HVAC systems and energy use. These four changes are ones owners will want to be aware of and ask about as they undertake new projects.