4 Powerful Approaches to Collaborative Project Delivery

By James T. Cicero and Rocco Gallo | Mar 28, 2019

Though we’ve been talking about design-assist for the past year, it isn’t the only path for collaborative project delivery.

In this article, we look across the project delivery landscape. We outline four powerful options for increasing collaboration on projects: Integrated Project Delivery, Lean, design-assist, and design-build.

Integrated Project Delivery (IPD)

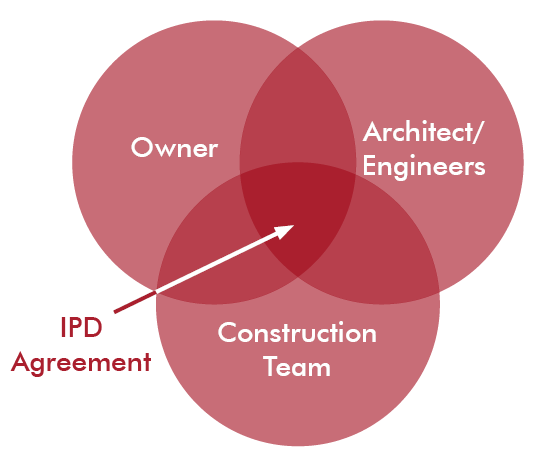

IPD is the most collaborative of project delivery methods. Three key characteristics define IPD: contract, process, and culture.

Distinctive contract: With IPD, key project stakeholders (such as architect, engineers, and contractors) have a single agreement with the owner.

As part of the agreement, they put their profit at risk, contingent upon meeting certain project goals. They also have the opportunity to earn incentives, which are performance-based and usually tied to quantifiable metrics. With an IPD contract, the team has skin in the game. That alone can motivate a team to higher levels of behavior.

Additionally, unlike typical contracts, which basically list deliverables and ways to work out disputes, an IPD contract discusses team structure, behaviors, and design processes.

Process: Successful IPD projects incorporate both Lean and design-assist. As noted above, design tools are embodied in the contract.

I originally believed that I didn’t need a contract to enforce my behavior. Team-oriented people should be well suited to our industry to begin with. As I experienced the IPD (ConsensusDocs) agreement, I found out how complementary it is to teaming and Lean. Since we designers are mostly “process driven,” the processes in the contract (whether related to behaviors or design) support the team approach. – Rocco

Culture: The IPD culture is collaborative. Team members come out of their traditional silos. They are on a level playing field, where cross-discipline contributions are welcome and important (for example, the electrical contractor may have knowledge that adds value to the architect’s work on the floor plan). They learn about their team members’ work and business. The process can foster empathy among team members.

The owner plays an important role in helping to create a “one team” culture. If they’re not truly on board with IPD, the rest of the team may struggle to work as a unit.

Learn More

For a solid, quick overview of IPD, check out “What Is Integrated Project Delivery?” at Lean IPD.

Lean

Lean is a methodology and a mindset, rather than a delivery method. It comes to the design and construction industry from the manufacturing industry.

With Lean, teams add value to projects by increasing efficiency and by decreasing waste. They use Lean tools and processes to improve decision-making, share knowledge, and streamline design and construction. They adopt a Lean mindset of continuous improvement, consistently looking for ways to deliver greater value. Lean is inherently team-oriented. Successful implementation depends on the contributions of all stakeholders.

The Lean Construction Institute (LCI) identifies 6 pillars (or core objectives) of Lean:

- Optimize the whole

- Removal of waste

- Focus on process and flow

- Generation of value

- Continuous improvement

- Respect for people

LCI places “respect for people” at the center of its model for Lean construction, calling it “the cornerstone of Lean thinking” (Source).

When using Lean, these are some common tools teams might leverage:

- Choosing by Advantages

- A3 decision-making

- Target value delivery

- Milestone planning

- Phase/pull planning

- Gemba walks

- 5 Whys

Lean isn’t limited to IPD projects. You can apply Lean to more traditionally-delivered projects, as well as within offices, departments, or teams.

Learn More

- Lean Construction Defined

- This Is Lean: Resolving the Efficiency Paradox by Niklas Modig and Pär Åhlström

- Lean Construction Glossary

Design-Assist

Design-assist is a tool rather than a delivery method. The goal of design-assist is to reduce project risks and improve overall project quality.

With design-assist, trade partners join the team while design is underway, rather than after bidding (as with traditional delivery methods). As a result, designers and contractors have early access to each other’s expertise.

The design team does the work they have always done: Field surveys, design concepts, calculations, system selections, building design. The construction team contributes their expertise during the design process. They provide input on site conditions, constructability, means and methods of installation, and cost. Together, designers and contractors work toward a final product that meets the owner’s objectives. Their back-and-forth collaboration helps them to optimize the both design itself and the construction process.

Together, the team can reduce risks related to:

- Budget & scope

- Schedule

- Errors & omissions

- Existing conditions

- Combative project environment

- Profitability

Owners can use design-assist, in varying degrees, with both traditional (e.g., design-bid-build) and collaborative delivery methods.

Learn more

- What Is Design-Assist?

- How Design-Assist Reduces 6 Common Risks on Projects

- 5 Ways Design-Assist Brings Order to Infrastructure Projects

Design-Build

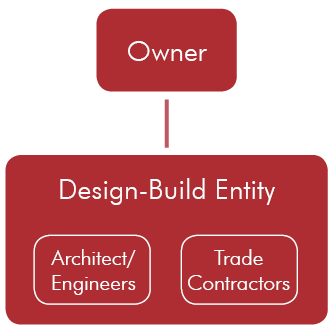

As a delivery method, design-build has a reputation for fast and inexpensive. An owner hires a design-build firm to complete a defined scope of work and specified performance standards. The owner gives up a certain amount of control over the project for the efficiencies of the design-build method.

Contractually, design-build gives the owner a single point of responsibility: The design-build firm holds a contract with the owner, and then the other project partners are contracted under the design-build firm. Here’s one form design-build can take:

Design-build provides opportunities for schedule and cost efficiencies, such as through early equipment acquisition and the lack of a bid period. Plus, with contractors on board early, they are much more in tune with the design.

Because its contract structure brings designers and contractors under one agreement, design-build can be a path to highly-collaborative project delivery. Design-build is also a good candidate for design-assist, because the design-build firm already has the relevant project partners (designers and contractors) on board.

Design-build can work to the advantage of owners who want a collaborative delivery process, but don’t have the time or resources to implement IPD or even CMR with design-assist. By using design-build, an owner can minimize their hands-on effort and still foster a collaborative process among the construction manager, design team, and trade contractors.

Learn More

- What Is Design-Build?

- Choosing a Project Delivery Method: A Design-Build Done Right Primer

- Revisiting Project Delivery Performance (Study)

Each of these approaches has its advantages and challenges. What’s true across the board, though, is that collaboration doesn’t happen automatically. In an industry defined by silos, teams need intentional leadership, thoughtful planning, and clear expectations to succeed at collaborative project delivery.